Design Studio: 3D Printers

3D Printing Services

- Submit files for 3D Printing. No self-service. TAs manufacture parts for you.

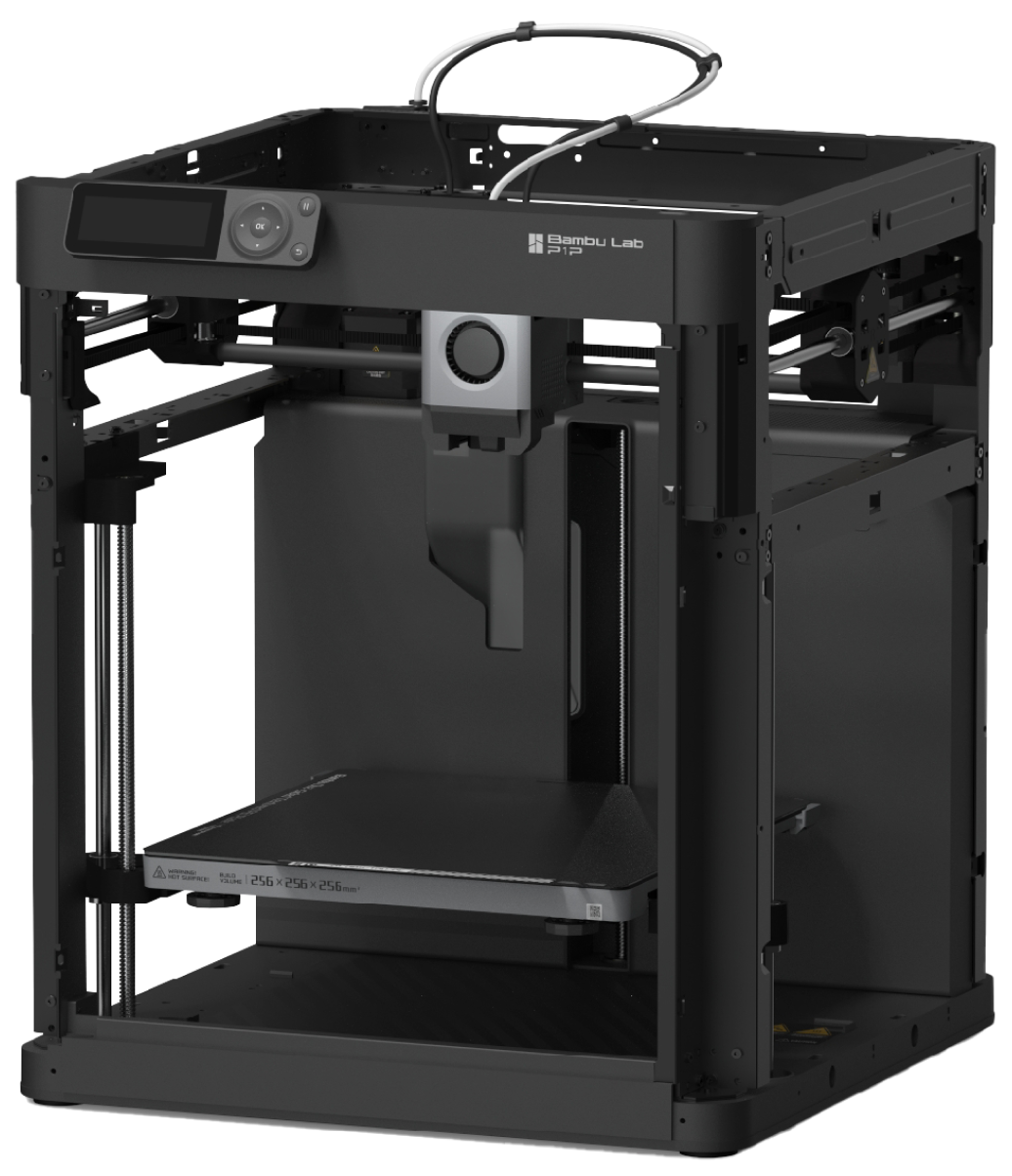

- Default printer is Bambu P1P with .STEP input file.

- Default material is PETG, but custom prints in TPU, PLA-Carbon, and ABS are also available.

- Custom printers include Bambu X1-Carbon and Stratasys F170

- Max print volume on all units is 256 mm x 256 mm x 256 mm.

- Printing service only available for coursework, RSOs, and research activities held in Design Studio. No personal projects.

- Recommend design consultation with TAs prior to custom print requests. See TA Office hours or email the TA team at 3dprintfab@udel.edu.